19.04 2022

The concrete floor of the first floor of utility and industrial premises may begin to sag. Deformation and skewing of individual concrete slabs, damage to concrete elements at the seams, etc. are also possible. To repair and level the concrete floor, it is not necessary to interrupt the production process and dismantle the equipment.

If the floor of the first floor of a commercial or industrial premises is made of concrete slabs, the settlement of individual elements is permissible within certain limits. All preparatory work for arranging the floor must be done at a high level, otherwise, after some time of operation, the room will need repair of concrete floors. Strongly sagged and unstable concrete elements, as well as sagged or damaged edges of slabs will interfere with the normal course of production processes.

It is possible to remove the deformation of the concrete floor, raise and level the position of individual concrete floor slabs of the first floor with the help of Floor Lifting technology. The work can be carried out in the shortest possible time, without dismantling the equipment. This allows you to save time and money, which is impossible when using outdated methods of repairing concrete floors.

At the same time, during the repair of concrete floors using the Floor Lifting technology, the load on the concrete floor is not a disadvantage, but rather an advantage. Sometimes it even makes sense to first install new equipment, and only then perform work on correcting the level of the concrete floor. Having significant weight loads, it is easier to direct the maximum effort when injecting geopolymers to lower soil layers. The soil has compacted under the specified load, which will allow to obtain a more stable floor surface.

When repairing a concrete floor using the Floor Lifting technology, problematic areas of the floor can be put into operational condition as quickly as possible. Downtime and costs associated with the removal and replacement of concrete floors are practically absent here. And the technology itself with minimal impact on the customer’s business processes.

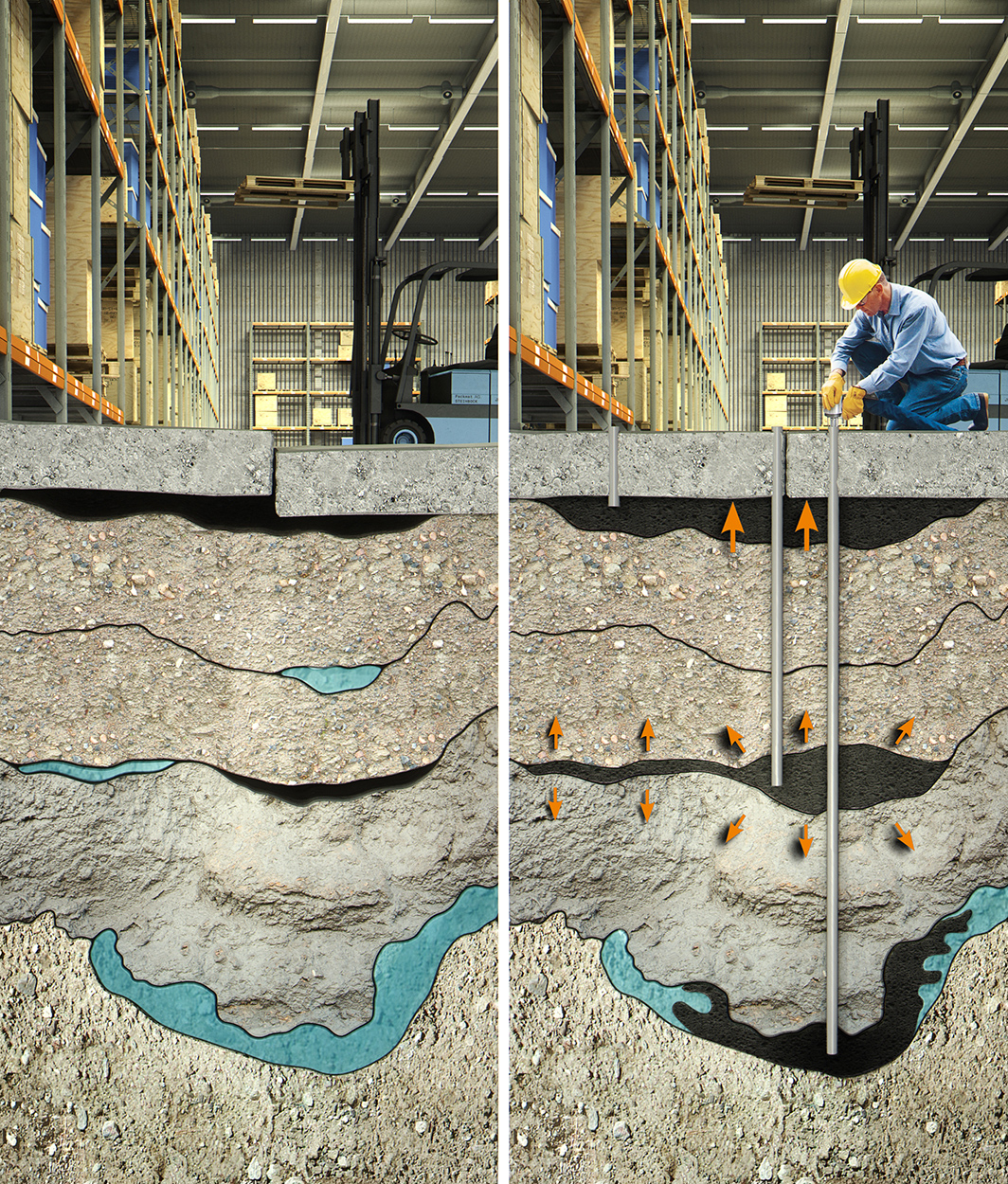

In order to level the position of concrete slabs, a series of injections of geopolymers are carried out directly under the slab through holes with a diameter of 8-12 mm. The constituent components of the material are mixed on special equipment, the chemical reaction of geopolymer expansion begins almost instantly. The geopolymer material fills cavities and voids, expands and compacts the weak bearing capacity of the soil layers under the slab.

Soil compaction occurs within a radius of 0.50 m from the injection site, and with the subsequent introduction of geopolymers, a layer with bearing capacity is formed, which becomes a support point for lifting the concrete floor slab. The lifting process is controlled and monitored during work. The lifting accuracy is ± 1 mm. After the work is finished, the holes for injection are closed.

Refrigerating warehouses have special requirements for thermal insulation. In order to maintain a negative temperature inside the room, such structures are insulated in a special way from all sides, including not only the walls and ceiling, but also the floor.

If you need to convert an existing warehouse, which is not equipped with reliable thermal insulation, into a cold room, geopolymers can also be used to level and insulate the floor or concrete slab foundation.

During the injection, two tasks are solved here. First, strengthening and compaction of the soil is carried out, which makes it possible to prepare the floor of the first floor for increased loads. Secondly, an additional layer of geopolymers under the foundation or floor of the first floor acts as a heat-insulating material. In this case, there is no need to bear additional costs for arranging thermal insulation of the floor of the refrigerating chamber.