Using geopolymer resins for injection is a quick and effective way to fix problems affecting the stability of major roads, bridges, tunnels, and public transportation networks. Geopolymers can be used to strengthen the soil under the road surface, as well as to lift and level sagging elements.

GeoResin often implements projects to restore a wide range of infrastructure facilities. Technologies used by our company can extend the life cycle of infrastructure facilities without disrupting the daily operation of the transportation network or affecting its users.

Maintenance of roads, highways, bridges, and crossroads

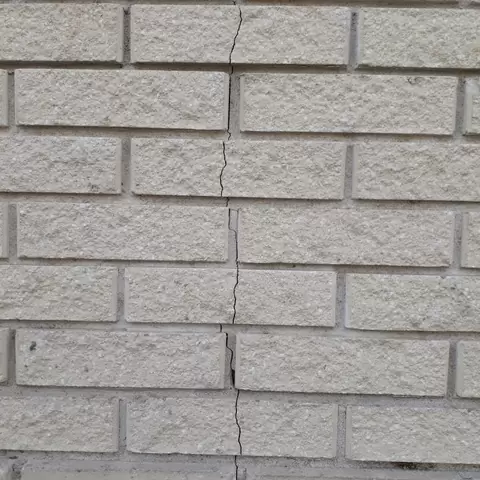

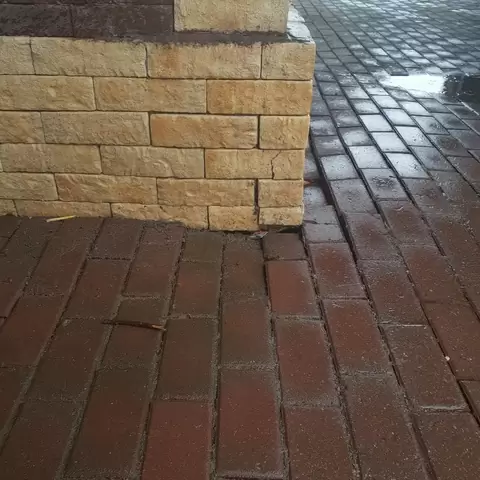

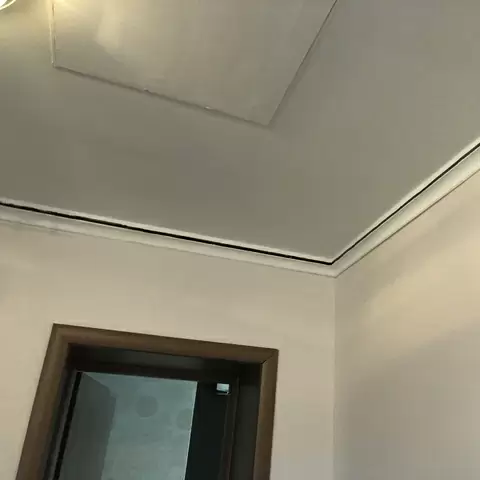

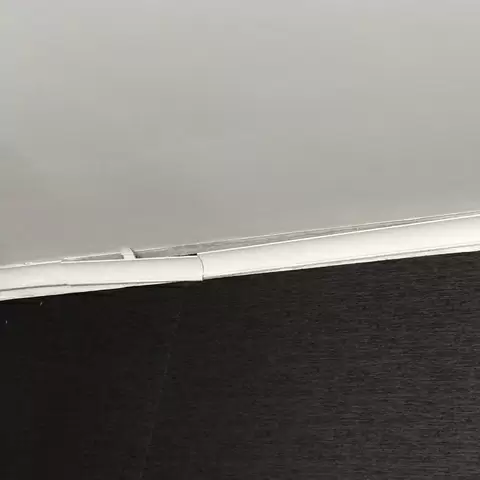

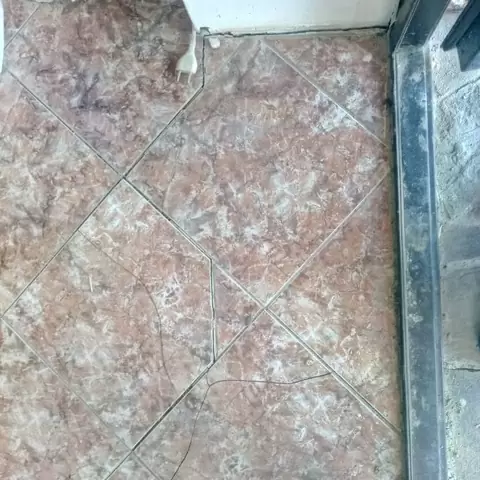

Long-term maintenance of a roadway can cause it to deteriorate. Various factors, such as overloading by large vehicles, exposure to the external environment, and others, can lead to ground subsidence and roughness on the road, which in turn leads to accidents and a decrease in the load capacity of the road. This problem occurs most often in high-traffic areas, parking lots, and truck maneuvering areas, at crossings between the roadway approach and the bridge, and at loading bays.

GeoResin geopolymer injection technologies allow to raise and eliminate subsidence. This is accomplished by injecting resin into the base of the road, which fills all of the free space, allowing for quick and effective reinforcement of the soil and leveling of the roadway. The solution is cost-effective and quick to apply, with minimal inconvenience to traffic.

Geopolymer injection method for lifting and leveling of road surfaces

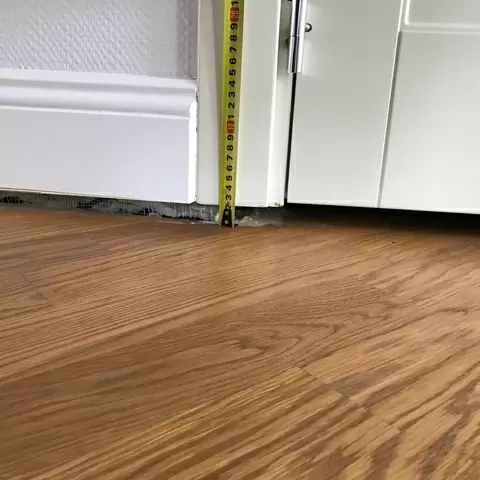

A geopolymer injection method called Slab Lifting can help restore the position of the roadway. It allows lifting and leveling of sagging areas, making it easier to repair emergency sections of roads, areas near bridges, railroads, port docks, loading docks, and other facilities.

Using the Slab Lifting method is more effective than traditional roadway repair methods. Advantages of the method:

- ·geopolymer resins are better able to withstand intense dynamic loads;

- ·restoration of a road or parking lot with geopolymer resins takes from a few hours to a couple of days;

- ·works can be performed in stages, without blocking all traffic areas, and at a convenient time when the traffic is minimal.

Traffic can be restored on the section repaired with geopolymers in 15 minutes after the completion of the work. Compared to the time it takes to restore a road section with dismantling and restoration of the roadway, which can take weeks or months, the use of the Slab Lifting method is a faster and more convenient solution.

Geopolymer injection technologies allow not only to restore the level of the roadway, but also to strengthen the base soil under the traffic way, or to strengthen the base when laying new highways and autobahns. When geopolymers are injected into excessively wet soils, excess moisture is displaced, which increases the bearing capacity of the roadway. The Deep Stabilization technique is usually used for this purpose.