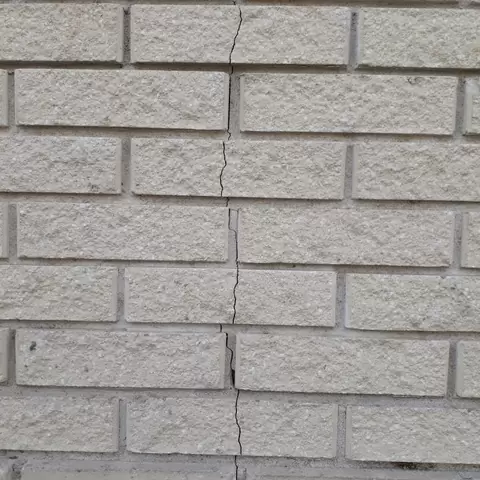

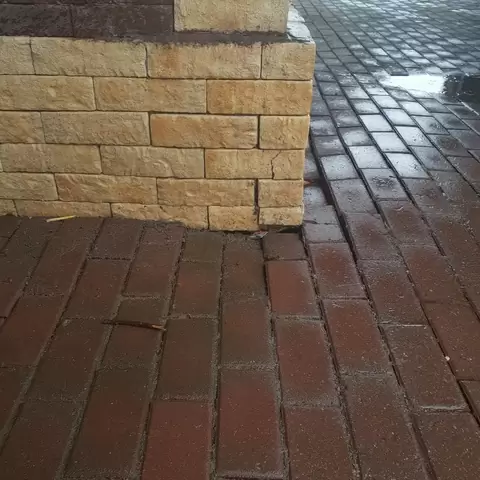

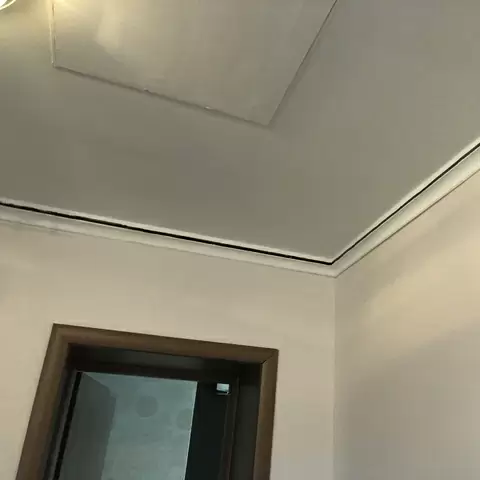

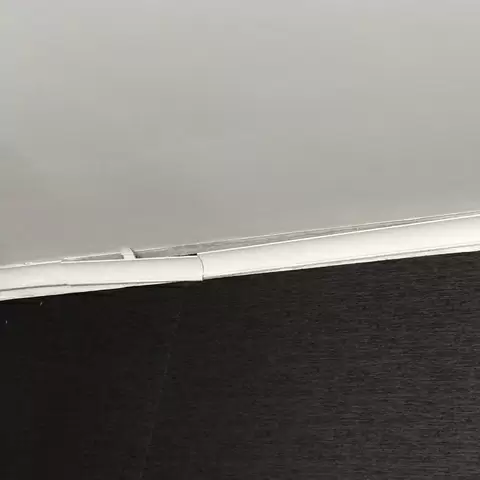

Subsidence of transport infrastructure construction bases, such as roads and bridges, can create obstacles to vehicle passage and lead to the formation of potholes and cracks in the road surface. As a result, it reduces road safety, increases the risk of accidents, and slows traffic. In the case of railroad tracks, subsidence can lead to disruption of train schedules and deterioration of safety at railroad crossings. The consequences can also include significant economic losses.

Georesin has many years of experience and ready-made solutions for the fast and high-quality lifting of transport infrastructure construction bases without dismantling and excavation works.

Lifting and stabilization of transportation infrastructure facilities using GeoResin technology

Sagging foundations of transportation infrastructure constructions are often the result of base problems. If a facility is built on unstable soils, such as loose soils, old landfills, peat bogs, or moving clays, it can be particularly susceptible to failure due to weather conditions, droughts, and flooding. Therefore, understanding what is happening to the soil beneath a transportation infrastructure facility is important in determining the cause of subsidence and choosing a method to correct it.

In its work on base leveling and strengthening, GeoResin uses geopolymer resins, materials that do not interact with water, which allows them to remain stable even in wet conditions. Thanks to this, GeoResin geopolymer injection methods can be used to lift and stabilize bases of all kinds of transportation infrastructure constructions, including infrastructure facilities in sea and river ports.

Advantages of lifting and stabilizing bases of transportation infrastructure facilities using geopolymer injection methods

The use of geopolymer injection methods to lift and stabilize bases of transportation infrastructure facilities has several advantages:

- 1. Quick and efficient.

- 2. Minimal harm to the environment. Geopolymers contain no toxic or harmful substances for the environment, which makes these methods environmentally friendly.

- 3. Durability. Geopolymers are highly resistant to moisture, UV rays, and other factors, which ensures constructions longevity after their stabilization.

- 4. Cost-effectiveness. Geopolymer injection methods are more cost-effective compared to traditional methods of repair and lifting of transportation infrastructure facilities.

Our solutions enable us to lift sagging areas and constructions without the need for long and destructive work. We can level small sagging areas in one day, as well as plan large projects so that re-leveling doesn’t bring the facility to a standstill.