Concrete floors are one of the most popular flooring types, with a wide range of use. Among their advantages are strength, wear resistance, unpretentiousness and the ability to create various textures on the surface. However, they also have some weaknesses. One of the most serious is collapsibility of the top layer. Georesin, which uses injection technology to strengthen concrete floors, will help to eliminate this drawback.

When it is necessary to strengthen the concrete floor

First of all, this procedure is used when the surface is damaged occurring due to:

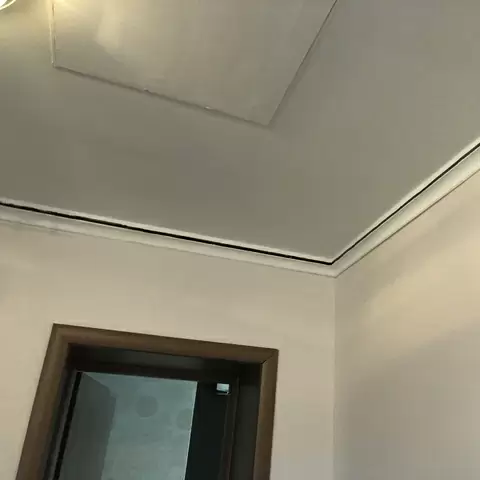

- · improper design and construction (insufficient reinforcement, incorrect choice of concrete quality, incorrect ratio of concrete mix components, violations of pouring technology, etc.);

- · exposure to aggressive environments (acids, alkalis, salts, oil products, sea water and other aggressive environments);

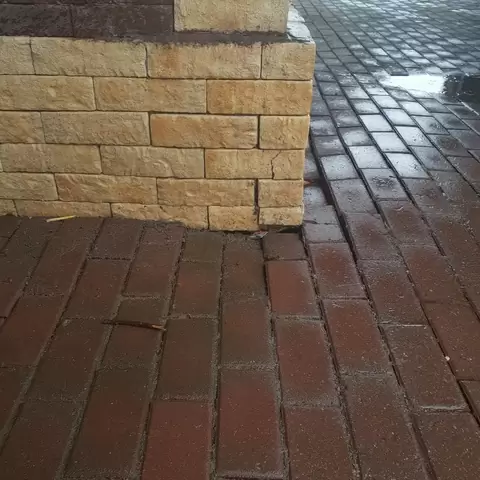

- · mechanical impacts (falling heavy objects, hits, friction, vibrations, overloads, traffic and people);

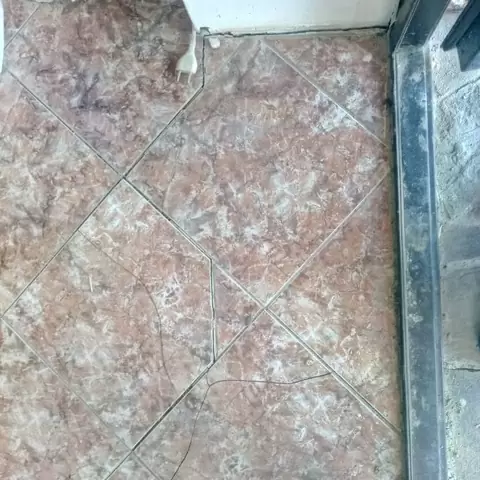

- · natural wear and tear;

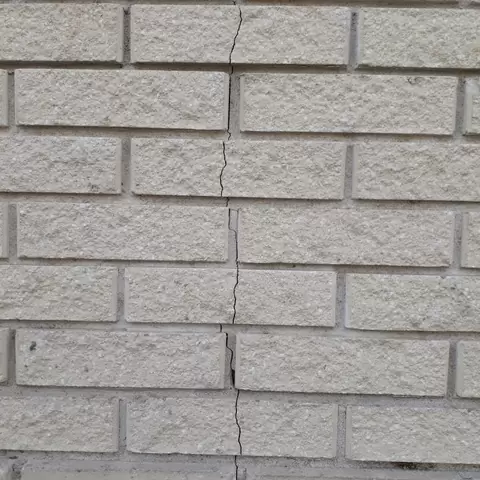

- · exposure to water (water entering the pores of concrete and its freezing can lead to cracks and destruction of the concrete surface);

- · adverse environmental conditions (extreme temperature changes, strong winds, earthquakes, floods).

Also, strengthening concrete floors is required in the following cases:

- 1. When planning an increase in load and changes in operating conditions – if it is planned to place heavy equipment, machines, cargo or other heavy objects beyond the design.

- 2. When designing and constructing a new building.

- 3. If the concrete floor does not meet safety standards, for example, is not strong enough or does not withstand the required loads, then it is necessary to reinforce the concrete to ensure the safety of all users of the premise.

The main ways to strengthen concrete floors

There are many ways to strengthen concrete floors. Let’s consider some of them:

- 1. Saw cutting is one of the most common methods of reinforcing concrete floors to prevent cracking and crazing of concrete surface. Saw cutting reduces tension in concrete that can result from temperature changes or mechanical exposure.

- 2. Grinding concrete is the process of removing the top layer of the surface using a special grinder. This procedure improves the floor appearance, increases its durability, improves antistatic properties and reduces the likelihood of dust on the floor surface. Furthermore, concrete grinding technology can be used to create a matte or glossy effect on the surface.

- 3. The use of reinforcing steel meshes. This is a method of strengthening concrete, which consists in the use of special reinforcing steel wire meshes. Reinforcing meshes help improve the strength and stability of concrete floors and prevent cracking.

- 4. Application of surface coatings. The method consists in applying various protective coatings to the concrete floor surface, such as wood, epoxy, polyurethane paint, rubber crumb. A self-leveling floor can also be used to strengthen a concrete floor, as it can improve its strength and wear resistance. These coatings protect the surface of concrete from aggressive influences, improve its resistance to mechanical impacts, and also improve its aesthetic appearance.

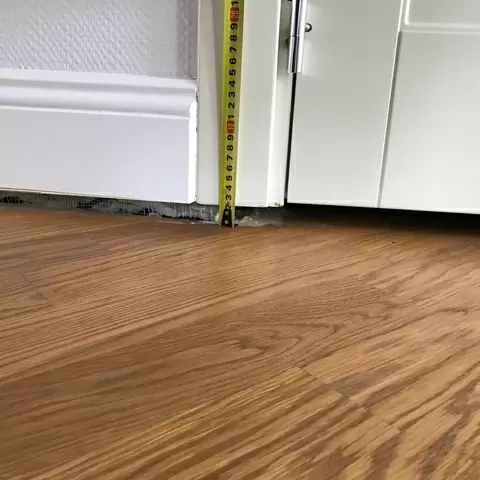

- 5. Filling voids under a concrete floor is also a popular method of strengthening the surface. It is used to increase strength and load capacity, eliminate deformations, and reduce the likelihood of surface failure.

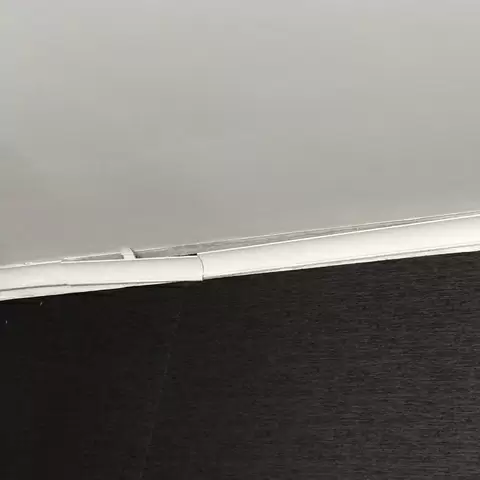

- 6. Use of injection materials. Injection materials are used to fill cracks and defects in the concrete floor. It is a modern and environmentally friendly strengthening method that helps prevent further crack development and improve the strength of concrete.

The choice of surface strengthening method depends on the damage nature, the causes of its occurrence, as well as on the specific conditions of its operation.

Stages of work to strengthen concrete floors

The plan of action and stages of work to strengthen the surface may vary depending on the chosen method and specific working conditions. But, as a rule, they include such activities:

- 1. Assessment of the concrete floor state before starting work, determining the nature of damages and the causes of their occurrence.

- 2. Selection of the optimal strengthening method that is most suitable for a particular case.

- 3. Surface preparation, which consists in cleaning the concrete floor surface from dirt, dust, oils and other contaminants. Grinding may also be needed to improve the adhesion of the new material to the floor surface.

- 4. Application of the selected strengthening method.

- 5. Completion of work. After applying the strengthening method, it is necessary to allow time for the complete hardening of the material. After that, a final quality check of the work and the necessary corrections are carried out.

After the work is completed, the concrete floor is ready for service. If necessary, regular care and maintenance of the floor is carried out to ensure its durability and keep it in good condition.

Advantages of working with Georesin

Georesin is a company that has been operating in the Ukrainian market for ages and has established itself as a responsible contractor. To strengthen concrete floors, we use proprietary methods of geopolymer injection based on maintenance requirement cards developed and approved in Europe and the CIS. We guarantee a facility’s lifetime extension, as well as its safety. The company uses environmentally friendly materials and disposes of all waste itself.