Concrete floors are resistant to moisture and fire, environmentally friendly and fairly budget-friendly. At the same time, concrete floors can be finished with a variety of materials such as paint, epoxy, tile and many others, allowing to create a variety of design and style options for the interior. But most of all, they are valued for their strength and durability. However, even the sturdiest material deteriorates over time and needs to be repaired. Georesin provides concrete floor repair services for warehouse, administrative, residential, and infrastructure projects.

Causes of cracks and hollows in concrete floors

Cracks and hollows in concrete floors can occur for a variety of reasons:

- 1. Improper concrete composition. If the concrete mixture does not have the correct ratio of cement, sand, gravel, and water, it can lead to cracks during curing. Also, such a floor is less strong and stable, which over time leads to the appearance of hollows and other deformations.

- 2. Excessive loads and mechanical impacts.

- 3. Temperature changes. Temperature fluctuations can cause concrete to expand and contract, resulting in its destruction.

- 4. Regular water exposure, which can cause destruction of the protective layer, reinforcement corrosion, resulting in damage to the floor.

- 5. Insufficient floor thickness. If it is too thin, it can not withstand the load, resulting in the formation of hollows.

- 6. Violation of the laying technology. Violations in the technology of laying concrete, such as improper compaction of concrete, can lead to cracks.

Major concrete floor defects and their elimination

There are several major concrete floor problems that can be corrected through repair work:

Hollows repair

When repairing hollows in a layer of concrete, rectangular notches are first created around the perimeter of the hollow to a depth of no more than 2 cm. Then the old coating and damaged concrete are removed, and then the swill and dust are removed. Next, the surface of the concrete is covered with a primer, and the hole is filled with a special mixture of cement, sand and water. After that, the surface is smoothed with a darby or a bump cutter. After that, a reinforcing steel net is placed on top to strengthen the repair. When the mixture dries, its surface is floated with a power sender to obtain an even and smooth surface. If necessary, the surface can be painted.

Elimination of unevenness

Errors in the technology of laying mortar can lead to unevenness in the concrete floor, which is one of the types of defects that reduce the strength of the structure. To eliminate such irregularities, a milling device is used. The process begins by creating deepenings in the lower level of the floor, which are then roughed off. After removing the dust, the area is reinforced with a primer.

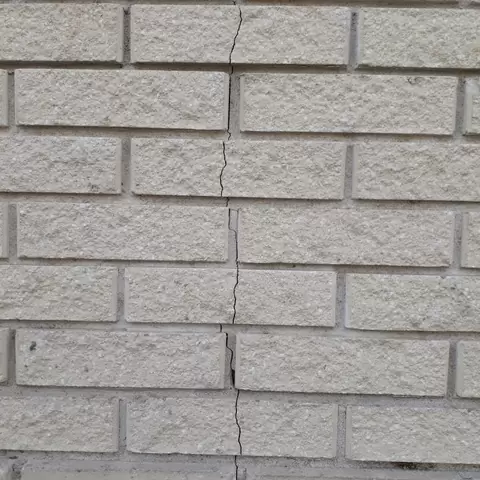

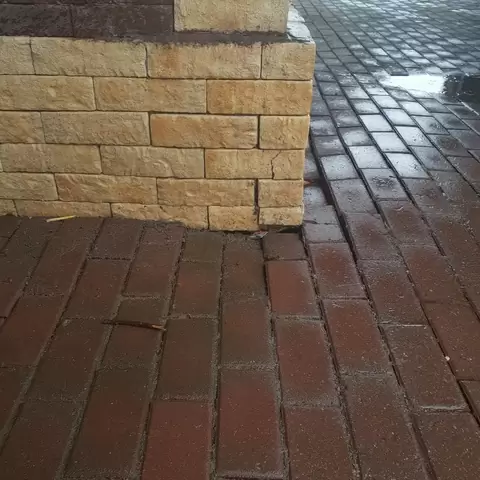

Cracks restoration

To prevent further expansion and protect against dust and moisture, cracks in the concrete floor must be repaired. To do this, you can use the method of expanding, which includes the creation of even cuts with a disk grinder, cleaning from swill and dust, treatment with a priming compound and filling with a special material. For long cracks in the surface of the concrete, metal staples can be used. To do this, the cuts are made with a certain pitch and depth, install elements of the reinforcement and produce concreting with the repair mixture until it hardens completely. After that, the surface is processed and grinded to the level of the entire surface.

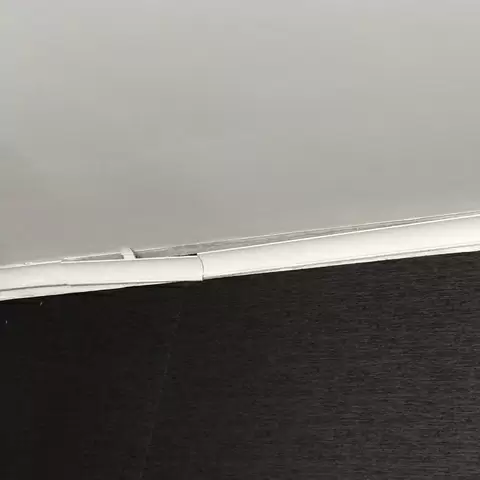

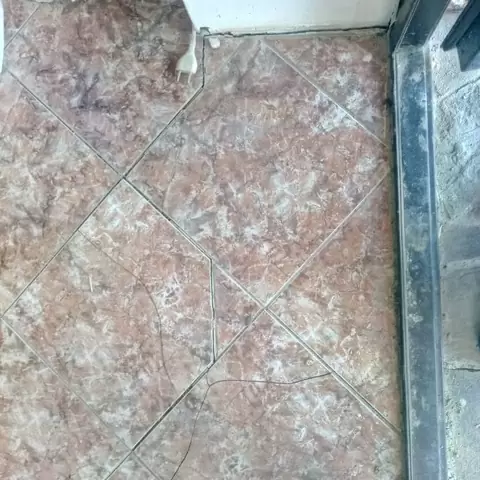

Concrete foundation joints repair

One of the methods to repair the leak resistance damage and deterioration at joints involves expanding the problem area with a diamond disc, removing swill and flaking areas. An epoxy primer is then applied to the inside of the joint and the joint is filled with a mortar of cement and polymer. Along the length of the joint, marks are set with a special marker-rod, observing a step of at least three meters. After the curing of the repair compound, the joints are grinded, the previously fixed marker-rod is removed and a new expansion joint is cut in that place. Finally, the resulting dust is removed from the joint and it is sealed with silicone sealant.

De-dusting

Frequent and intensive use of the concrete surface can produce large amounts of cement dust, which is harmful to human health and can damage the integrity of the floor, leading to its destruction. The only way to solve such problems is to repair the surface.

To reduce the amount of dust on the surface, you can use dyeing agents or a special compound like a filler floor, which is used to cover the problem areas. The compound gets 0.5 cm deep into the screed, and acts as a barrier against dust. Such materials are resistant to chemicals and increase the strength of the material. In addition, the use of such products can protect the surface from negative temperature effects.

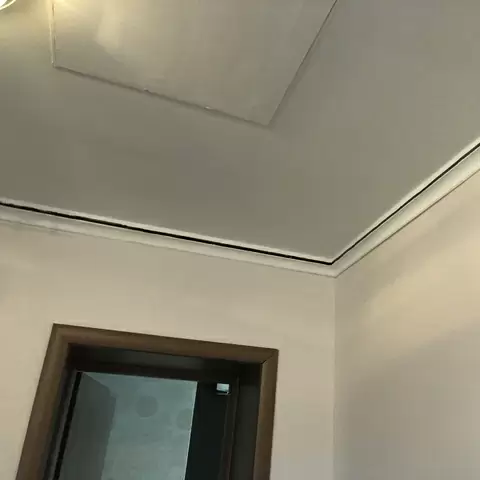

Restoration of screed flooring

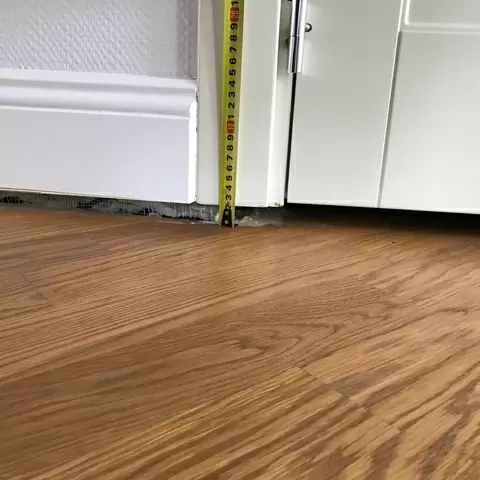

If floor screed repair is necessary, the methods of repair work depend on the type of defect. The most common screed problems are chips, cracks, flakings, and hidden bugholes. To identify voids, the method of tapping with a metal rod on the floor is used, in the broken areas of the screed when tapping a muffled sound is heard. If the damaged area exceeds 30%, the screed must be completely replaced. If the damaged area is smaller, restoration is possible.

The advantages of working with Georesin

The Georesin company has been working on the Ukrainian market for a long time and has a reputation of a responsible contractor. To repair concrete floors we use authors’ methods of geopolymer injection, based on the technological charts, developed and approved in Europe and Ukraine. We guarantee an increase of service life of the object and ensure its safety. In addition, we use environmentally neutral materials and recycle all waste. The price of concrete floor repair depends on the area and type of damage, the specifics of the object and materials used. Get more information from Georesin consultants.